3D-MC Max Machine Builder

Reference Material

3D-MC Max Quick Guide 1010717-01

3D-MC Max Dozer Install Manual 1009522-01

Verify FW and SW - Check for Max .mx3 Options

If loading FW and SW. Firmware needs to be loaded before GNSS Oaf’s (.tpo)

Confirm 3DMCMax Auth Code (.oaf) is Enabled/Yes on GX-55Create Configuration Name/Type: 3D Max

Mounting location: Cab Roof Front & Rear

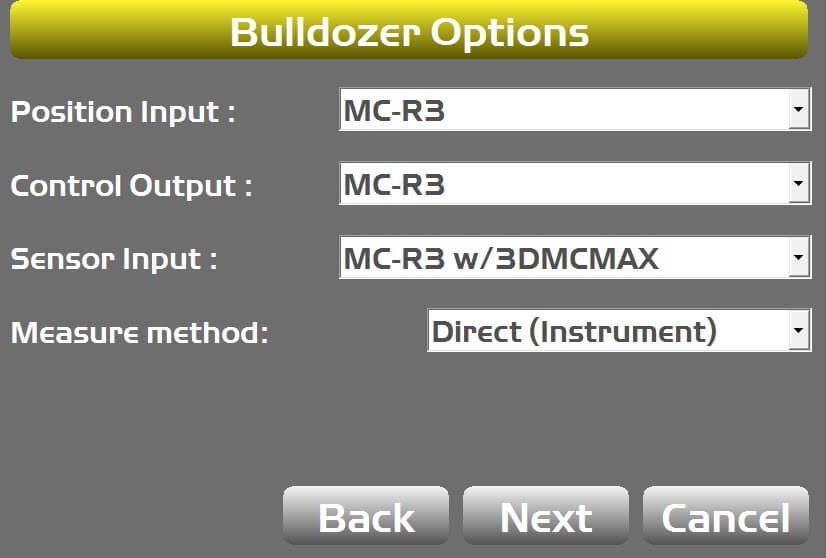

Dozer Options

Sensor Input: 3DMCMAX

Measure method: Direct (Instrument)

Measure machine

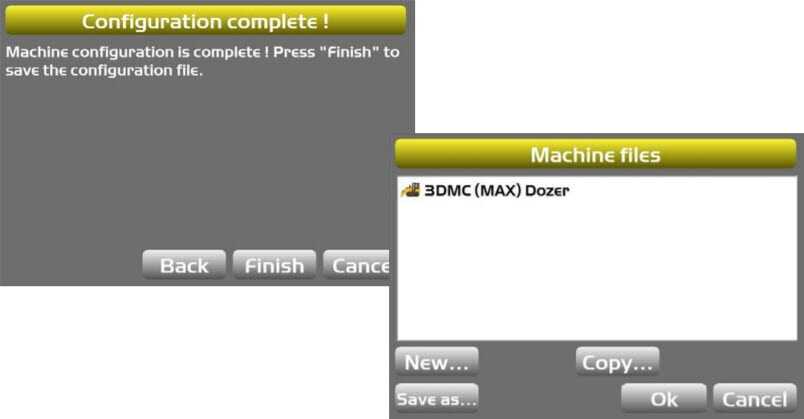

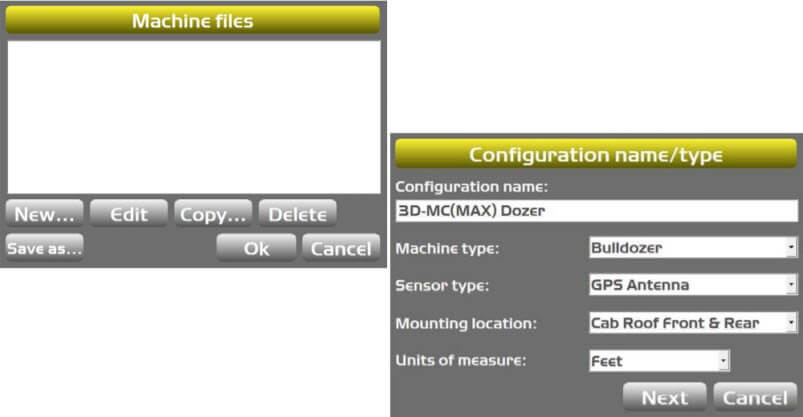

Create New 3D-MC Max Machine Builder

Create Machine Builder

In the 3D-MC Max main screen

Tap Power Button (GX-55)>Control>Machine Setup. The Machine files appear.

Tap New. The Configuration name/type appears

Enter machine name: Max Dozer

Mounting Location: Select Roof Front/ Rear or Single

Bulldozer Options

Measure Method

Tape Measure: Uses slant measurements to determine antenna height/position

Direct (Instrument): Uses straight-line measurements from a laser/total station to establish antenna height/position.

Direct (Instrument) recommended: Tape measure has room for error with track sag, angle of tape to track, surface side slope

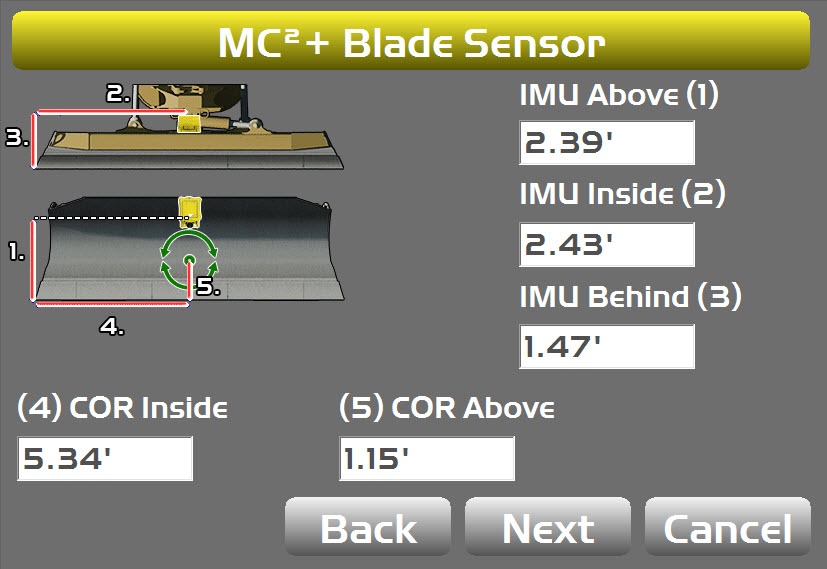

Direct (Instrument) Measurements Blade Sensor

MC2+Blade Sensor

COR same as conventional 3DMC2

All measurements are from the right side of the blade sitting in the cab.

Measure to Reference Point on IMU

IMU Above: From cutting edge to IMU RP

IMU Inside: From right cutting edge/end bit of blade to IMU RP.

IMU Behind: From cutting edge to IMU RP

COR Inside: Center of Blade Rotation to right side of cutting edge

COR Above: From cutting edge to Center of Blade Rotation

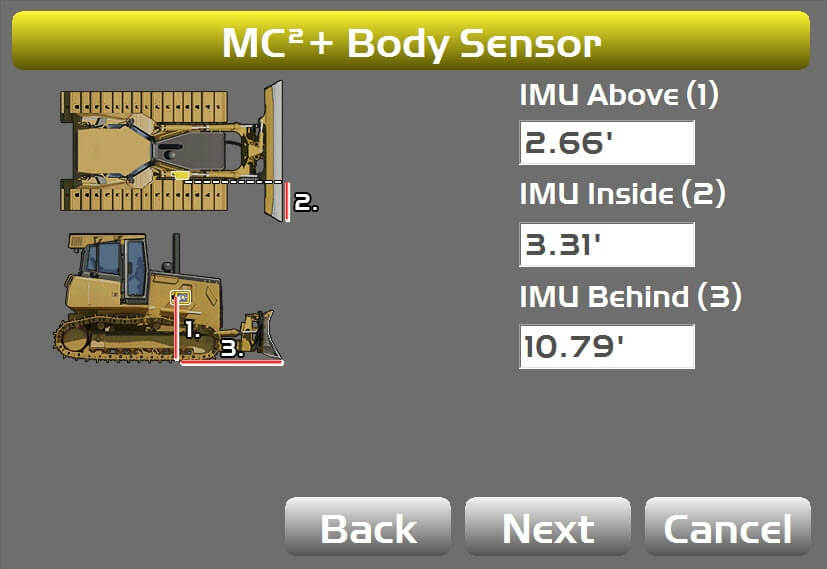

Direct (Instrument) Measurements Body Sensor

MC2+ Body Sensor

IMU Above: From cutting edge to Reference Point on sensor

IMU Inside: From right corner of blade to Reference Point on sensor

IMU Behind: From cutting edge to Reference Point on sensor

Body IMU Sensor mounted at Center of Dozer Body (not shown in this picture)

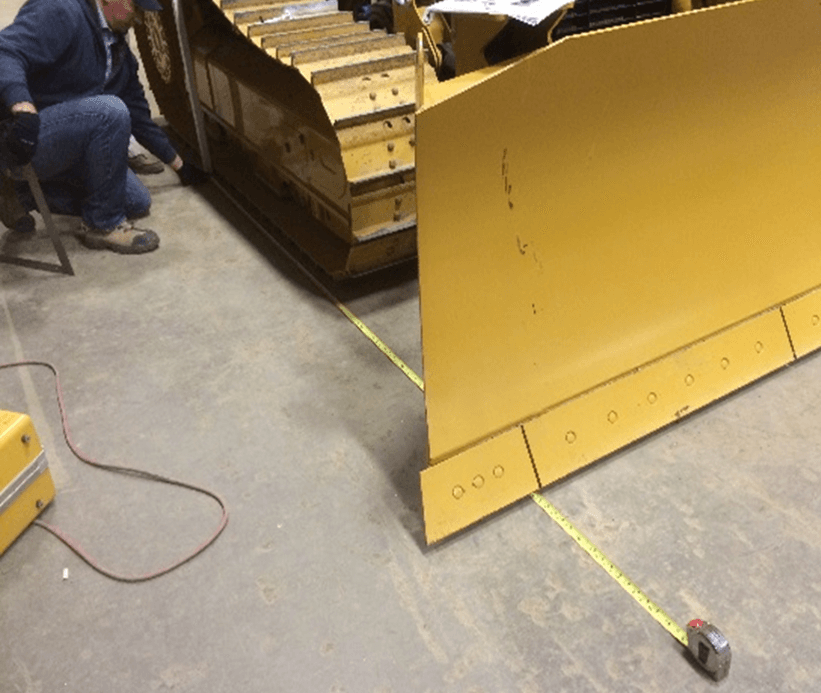

Performing this calibration requires flat surface between Blade edge and IMU for accurate measurement.

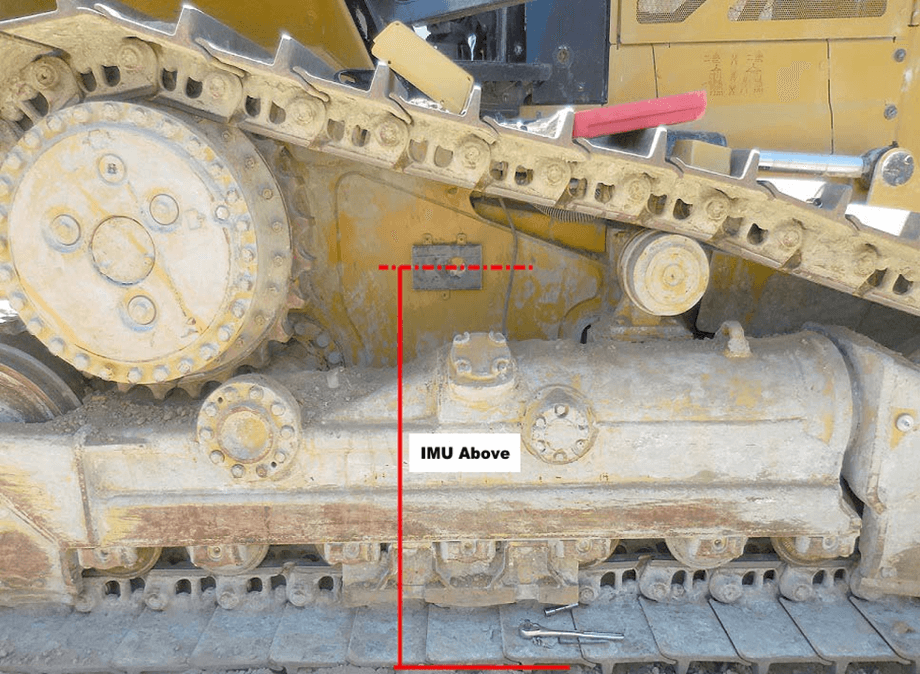

IMU Above Measurement

Use a level to transfer the Reference Point on the sensor to outside the tracks

Measure down with a tape measure to establish Body IMU Above measurement

IMU Inside Measurement

Use a framing square to establish right angle at corner of blade

Lay a grade rod down on the square and parallel to the track edge

Measure over from the reference point of the body sensor to the grade rod

IMU Behind Measurement

Use a level to transfer the Reference Point on the sensor to outside the tracks

Drop a plumb bob to the ground and mark it with a marker or paint

With the blade slightly raised, slide a tape measure under the blade back to the plumb bob mark

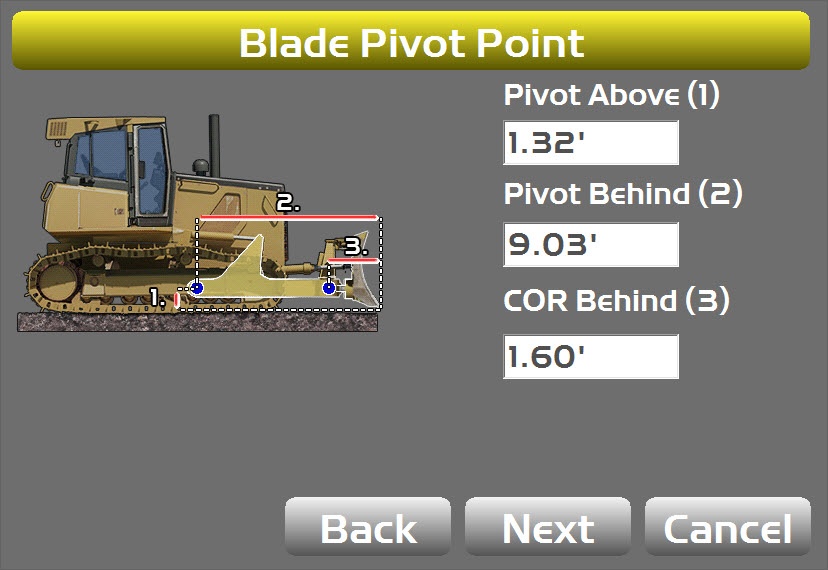

Blade Pivot Point

Pivot Above: From body pin on A-frame to center of tracks

Pivot Behind: From cutting edge to body pin on A-frame

COR Behind: From cutting edge to center of rotation

Pivot Above on most machine are difficult to get to

Pivot Above is important, this calculates antenna height

Blade Pivot Point is reference for Max system

Pivot Above

Use a tape measure to measure up from ground to the Reference Point

Pivot Behind

Drop a plumb bob to the ground and mark it with a marker or paint

With the blade slightly raised, slide a tape measure under the blade back to the plumb bob mark

COR Behind

Raise the blade slightly off the ground

Drop a plumb bob down from Center of Rotation

Measure from plumb bob to cutting edge to establish COR Behind

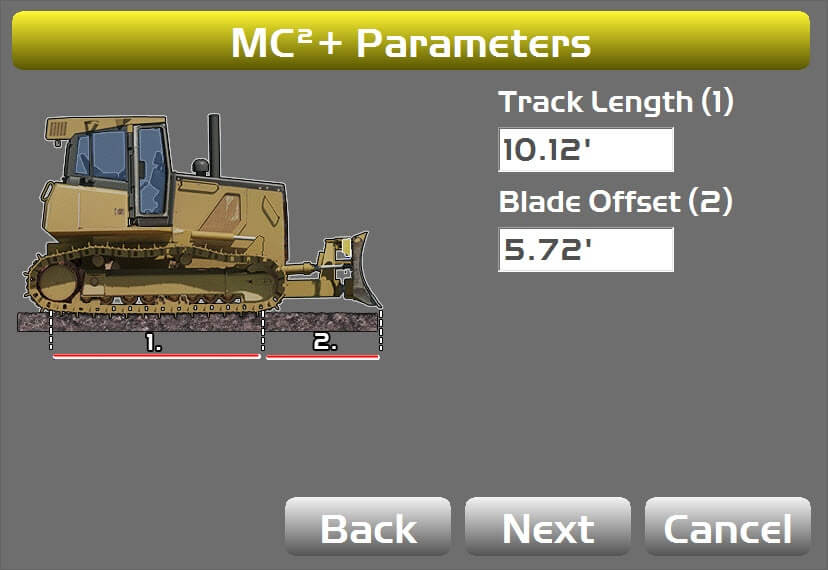

Track Length Blade Offset to Tracks

Track Length: Center of front roller to center of rear sprocket

Blade Offset: Cutting edge to center of front sprocket

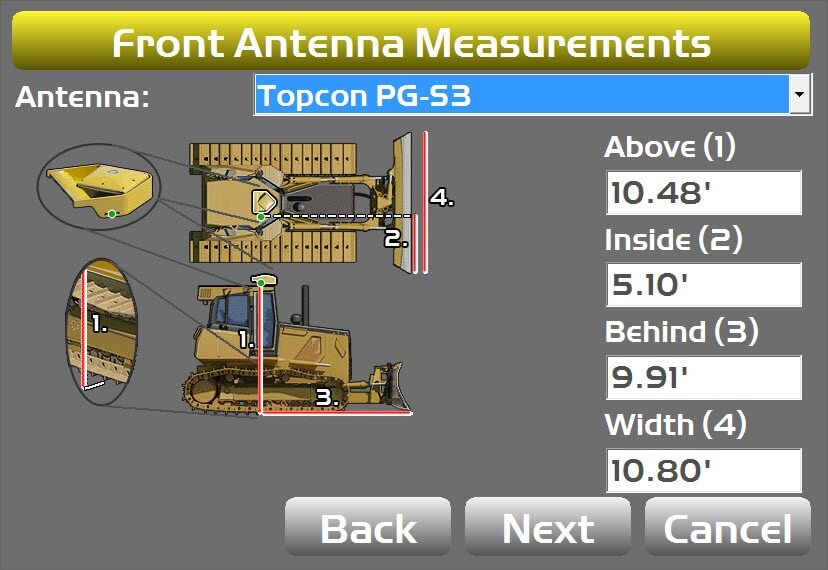

Front Antenna Measurements

Above: From slot on bracket to cutting edge

Inside: From right corner of blade to right side of bracket (not antenna center

Behind: From cutting edge to back of slot on bracket

Width: Width of cutting edge

All measurements are to the notch on the antenna bracket

Important to be on a flat surface making measurement

Front Antenna Above measurement used with Blade Pivot Above measurement for antenna height

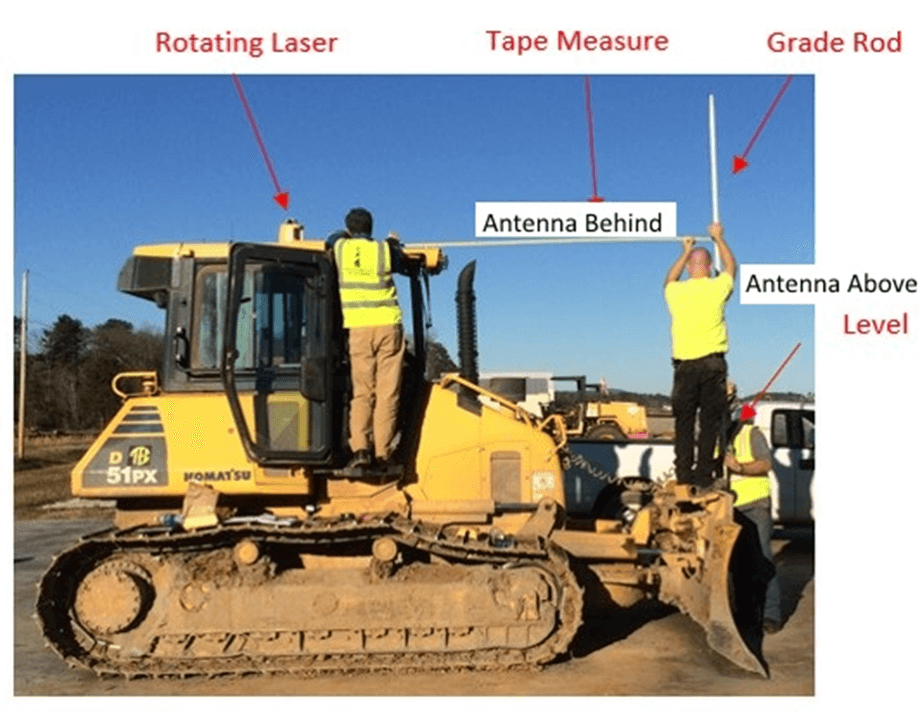

Establishing antenna above and behind measurements with Direct method

Laser

4’ Level

Tape Measure

Telescoping Rod

Many different methods to Direct (instrument) measure antennas for 3D-MC Max

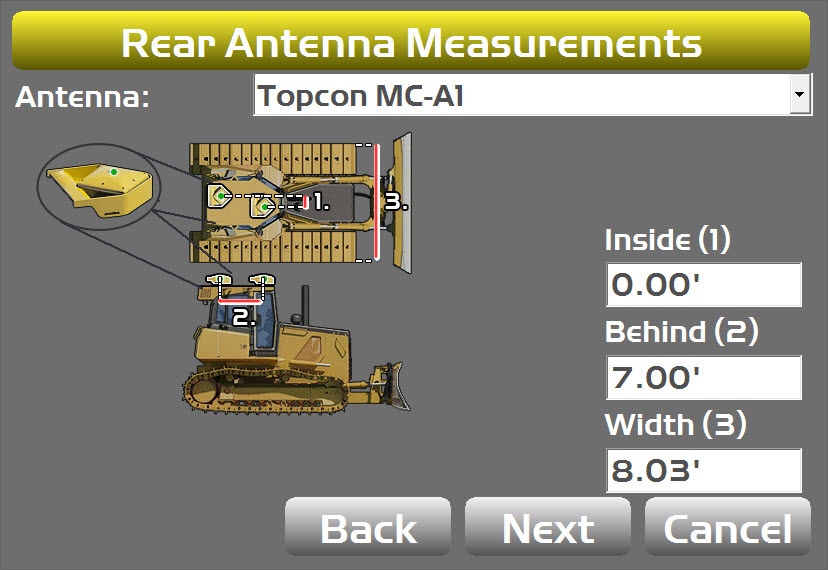

Rear Antenna Measurements

Inside: From center of front antenna to center of rear antenna offset

Behind: From of front antenna to center of rear antenna

Width: Width of machine measuring tracks

3D-MC Max Machine Build Complete

Direct (Instrument) Measurement Complete

For best result, measure and calibrate on a flat planar surface

Important to have Front Antenna Above and Blade Pivot Above measurement very accurate

PS recommends Direct (Instrument) Measurement

System will not transfer measurements from Tape to Direct measurements

When making new .mx3 the slope calibration do not carryover.